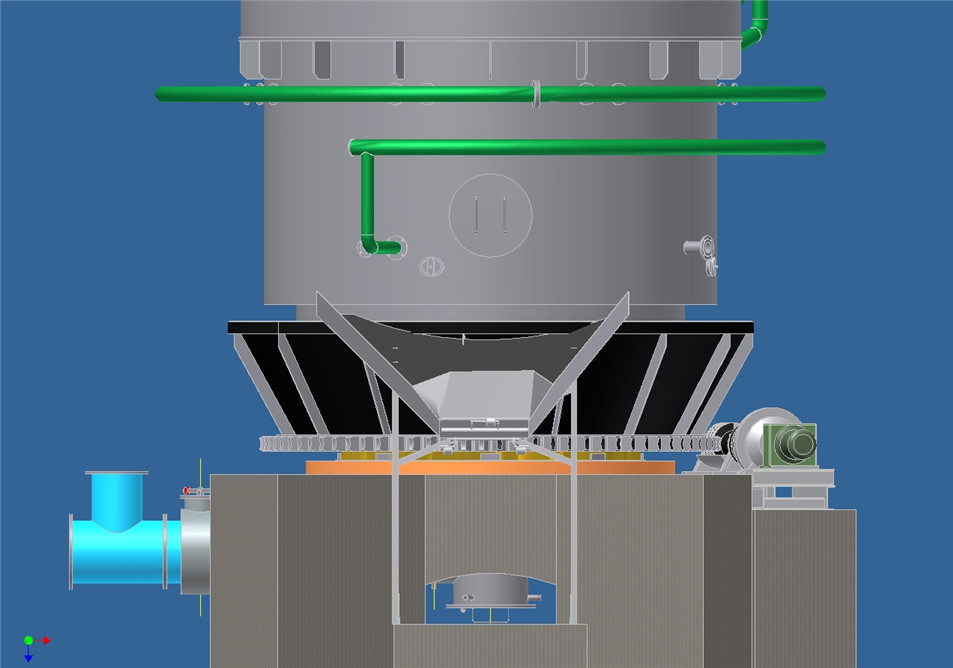

Two-stage Gas Furnace

0086-13506407229

Introduction

Using the unique dry distillation method, the high-efficiency and energy-saving two-stage gas generator has achieved the goal of energy saving and environmental protection. Huangtai two-stage furnace machine series products won the title of national new product prize of scientific and "first prize" technological progress, "excellent project prize" in the Chinese Zhongyuan international engineering company (the original machinery & design institute), and access to national "science and technology achievement award", scientific and technological achievement award of Shandong province," silver medal of spark plan exhibition SEC in Shandong province ". It is a recommended "high-efficiency and energy-saving environmental protection product" by the national science and technology commission.

Application

two-stage gas generator is widely used in steel, ceramics, metal magnesium, alumina, refractories, glass, metallurgy and other industries.

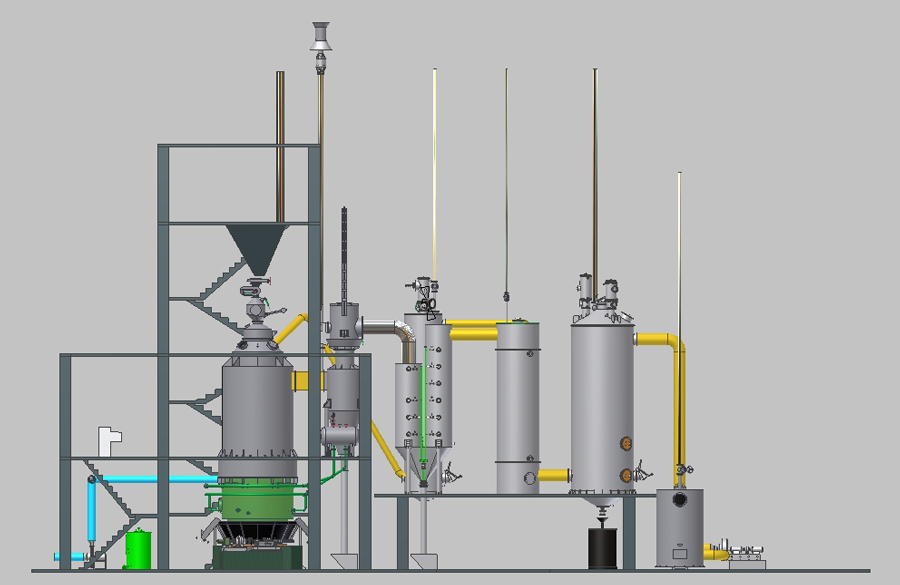

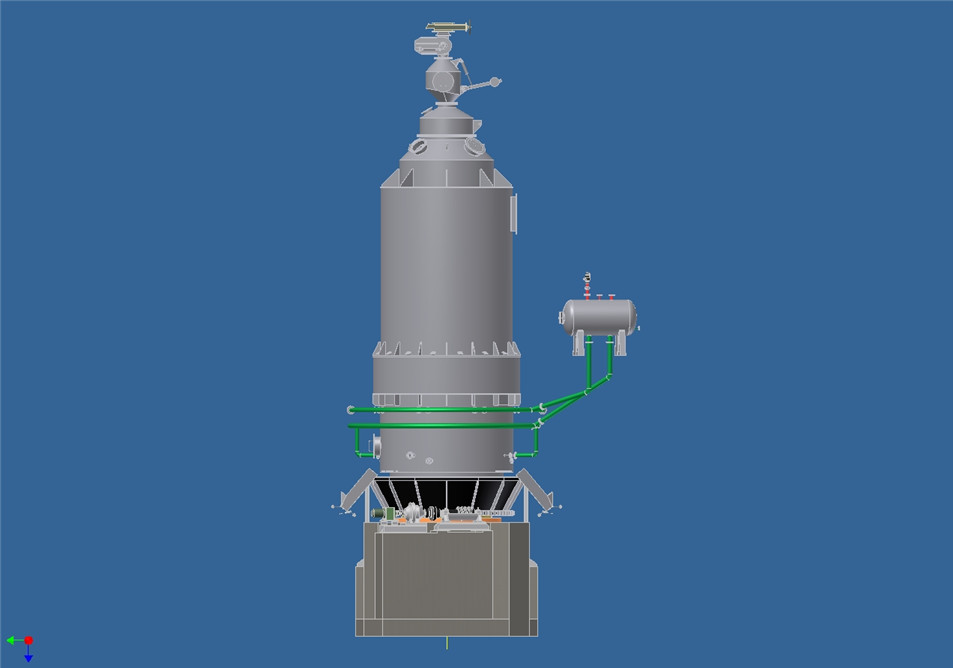

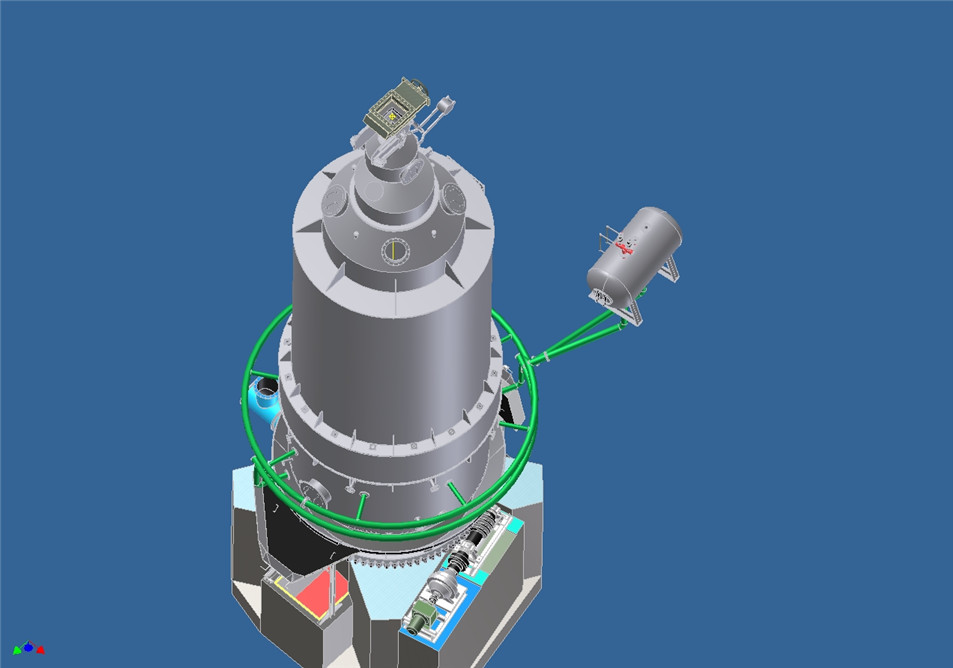

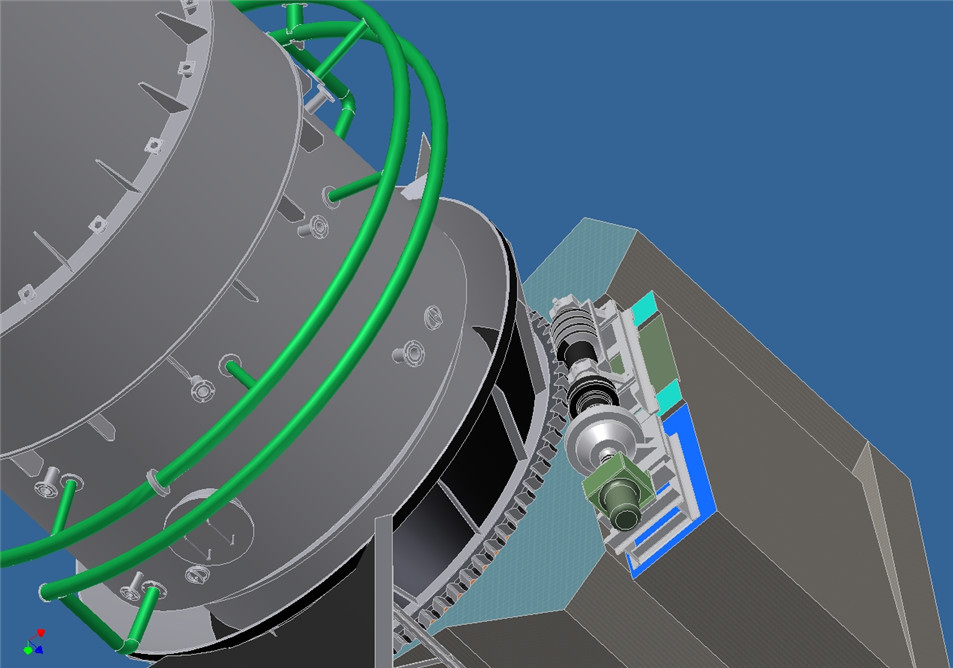

Qualified coal for gasification is added into the coal furnace by the automatic stoker. After dry distillation, the semi-coke moves down to the gasification section and reacts with gasifier to form gas (gasification agent is composed of air and steam).The gas produced by gasification section is divided into two parts: one part is drawn from the gas outlet of the lower section of the furnace, and the other part is from the upper section mixed up with the dry distillation air. The gas exported from the lower section enters the cyclone dust collector, wet disc valve and the ash hopper for dust removal and then enters the gas main pipe. The gas exported from the upper section first enters the electric tar-catcher to remove the tar, and then mixes up with the gas from the lower section in the gas main pipe. Finally, the mixed gas is sent to each gas supply point by gas pipeline.

|

Model

|

D2.0

|

D2.4

|

D2.6

|

D3.0

|

D3.2

|

D3.4

|

D3.6

|

|

furnace inner diameter

(m)

|

2.0 | 2.4 | 2.6 | 3.0 | 3.2 | 3.4 | 3.4 |

|

furnace sectional area

(㎡)

|

3.14 | 4.52 | 5.3 | 7.07 | 8.04 | 9.08 | 10.18 |

|

Working pressure of water jacket(Mpa)

|

0.294 | ||||||

|

steam output of water jacket(Kg/h)

|

~340 | ~380 | ~420 | ~550 | ~650 | ~690 | ~710 |

|

Fuel fragmentation and coal type(mm)

|

20-40、25-50、30-60non-caking 、weakly caking coal、long flame coal 、lignite and gas coal | ||||||

|

Fuel consumption(Kg/h)

|

630~950 | 1000~3000 | 1430~1630 | 2000~2670 | 2200~2750 | 2450~3100 | 2750~3350 |

|

Coal gas calorific value (low)(KJ/Nm³)

|

up stage7400~7800 down stage5500~6000 mixture6450~6900 | ||||||

|

Coal gas production(Nm³/h)

|

1900~2800 | 3000~4000 | 4300~4900 | 6000~8000 | 7000~9000 | 7800~9900 | 9000~11000 |

|

Gas temperature at furnace outlet(℃)

|

up stage100~150 down stage550~600 | ||||||

|

Blast pressure at furnace bottom(Pa)

|

<3000 | <6000 | <6000 | <6000 | <6000 | <6000 | <6000 |

|

Gas pressure at furnace outlet(Pa)

|

<1470 | ||||||

|

Note: gas production and calorific value are related to coal type and coal quality

|

|||||||

Two-stage coal gas generator is widely used in steel, ceramics, metal magnesium, aluminium, refractory material, glass, metallurgy and other industries. More case > >

大连特钢24万立煤气站 |

太阳镁业煤气站 |

河南中美铝业煤气站 |

中文简体

中文简体