Fluidized bed two-stage O2/steam gasification of agricultural biomass for low-tar syngas production: industrial testing and technological verification

Abstract: In the complete green synthesis technology chain, bio-syngas production remains the "first hurdle". Especially, the "tar" problem in biomass gasification urgently needs to be solved. Recently, our team, in collaboration with Jinan Huangtai Gas Stove Co., Ltd., completed a 10,000-ton industrial test and technical verification of biomass fluidized bed two-stage O2/steam gasification for production of syngas. The test results showed that the fluidized bed two-stage gasification device operated continuously and stably for over 110 hours with various biomass feedstocks. Additionally, the tar content in the produced gas was as low as 0.58 g/Nm3. And the fly ash collected from the continuous test had a carbon content of about 30 wt.%. The test results fully prove the technical feasibility and operational stability of the fluidized bed two-stage gasification technology in large-scale biomass production of high-quality syngas.

Keywords: industrial testing, technological verification, biomass, fluidized bed two-stage gasification, low-tar syngas, O2/steam gasification.

1. Introduction

The integration of biomass-based carbon sources with “green hydrogen” produced through photovoltaic-powered water electrolysis facilitates the catalytic production of sustainable aviation fuel and green methanol. This approach has become a prominent research focus in green low-carbon technologies globally, an emerging frontier for the energy and chemical sectors, and a pivotal technology for realizing the “carbon neutrality” objective [1-5]. Across the entire technology chain encompassing syngas production, purification, and catalytic synthesis, biomass gasification technology has yet to achieve industrialization breakthroughs either domestically or internationally. This shortfall has emerged as a critical “bottleneck” and “stumbling block”. Large-scale gasification technologies widely used in coal gasification, notably entrained-flow gasification, face challenges when applied to biomass fuels. These challenges stem from fundamental differences in composition, grindability, slurryability, and ash properties between biomass and coal. Large-scale fluidized bed technology represents the most viable option for biomass gasification. Nevertheless, two critical hurdles remain: mitigating the “tar” problem in biomass gasification and purification processes and accelerating the engineering scale-up and industrial deployment of bio-syngas production technologies [6-8].

The fluidized bed two-stage air gasification technology has been successfully deployed for converting bio-wastes from light industrial sectors, such as traditional Chinese medicine residues and distillers' grains, into fuel gas. In Henan, Sichuan, Shandong, and Anhui provinces, several industrial-scale demonstration projects with an annual biomass waste processing capacity of 10,000–50,000 tons have been commissioned. These initiatives have effectively attained internationally recognized technical benchmarks, featuring a tar content in the syngas of less than 50 mg/Nm3. [9,10].

2. Materials and methods

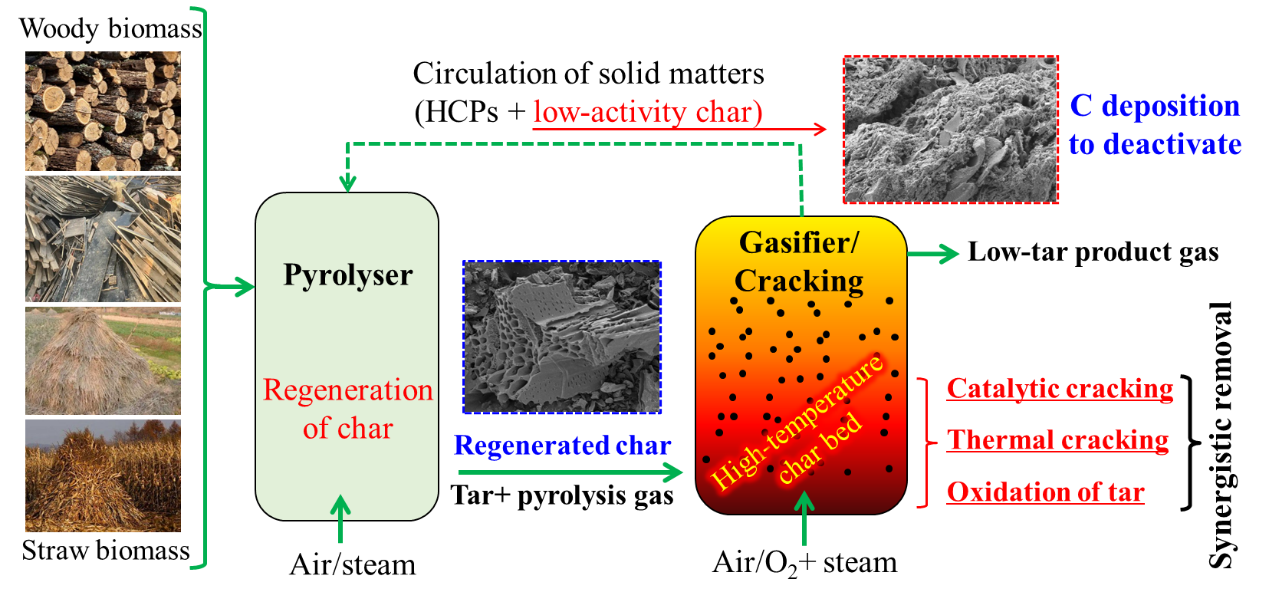

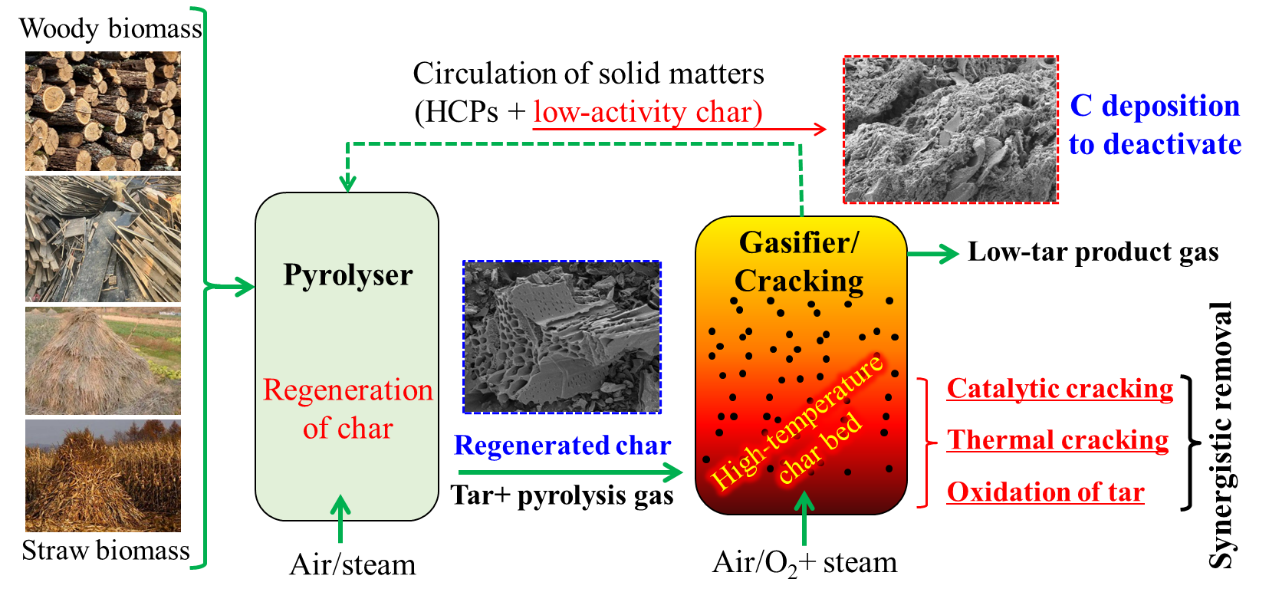

Recently, our team, in collaboration with Jinan Huangtai Gas Stove Co., Ltd., developed an innovative 10,000-ton-scale fluidized bed two-stage gasification pilot plant. This system employs two fluidized reactors to separate pyrolysis from char gasification and tar cracking reactions, creating a closed-loop “catalysis-regeneration” cycle for biochar (Figure 1). Leveraging thermal cracking, oxidative cracking, and high-temperature char catalytic cracking within the fluidized bed reactor, the technology synergistically minimizes tar formation, achieving the technical milestone of producing ultra-low-tar syngas from biomass[11-22]. Meanwhile, the innovative biomass gasification technology capitalizes on fluidized reactors’ inherent strengths—efficient heat and mass transfer and rapid reaction kinetics—to accommodate high-moisture, low-calorific-value feedstocks. The biomass pellet fuel employed in the industrial trials was procured from Shandong Province, China. Table 1 outlines its key properties.

Figure 1 Schematic diagram of the process for producing low-tar gas/syngas through a fluidized bed two-stage gasification system.

3、Results and discussion

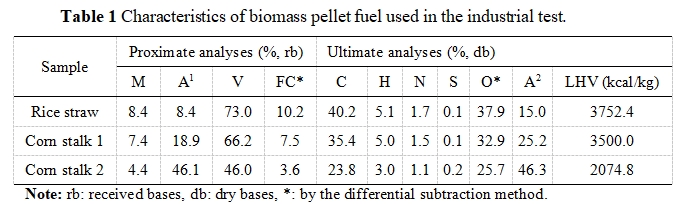

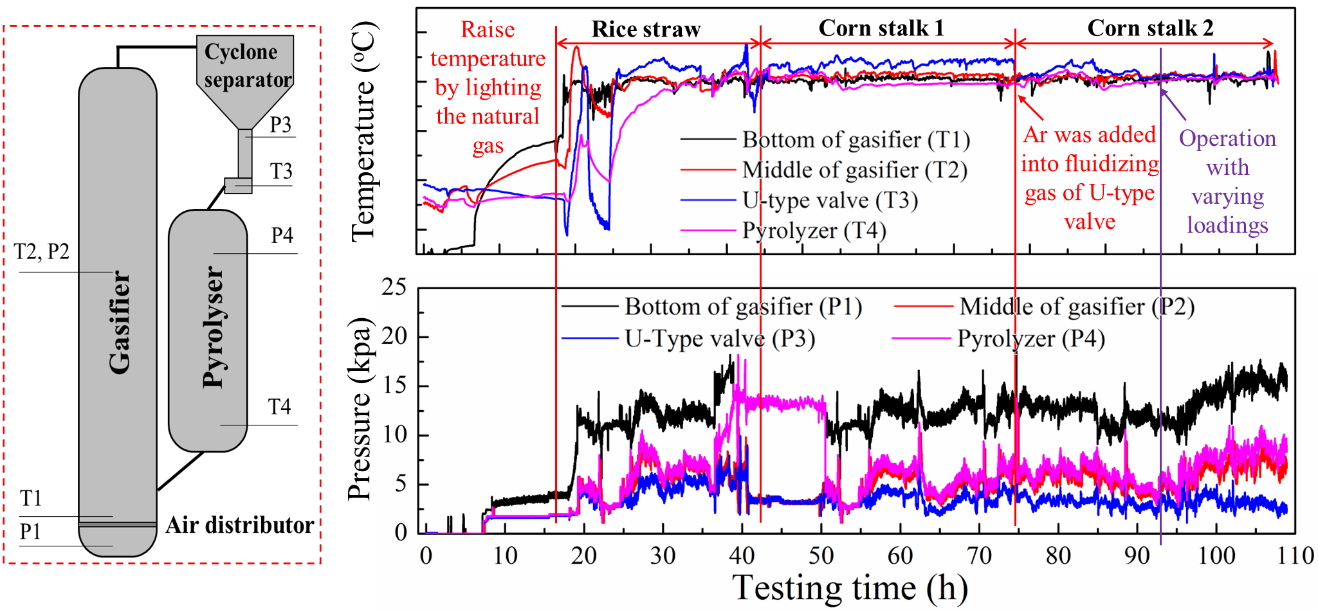

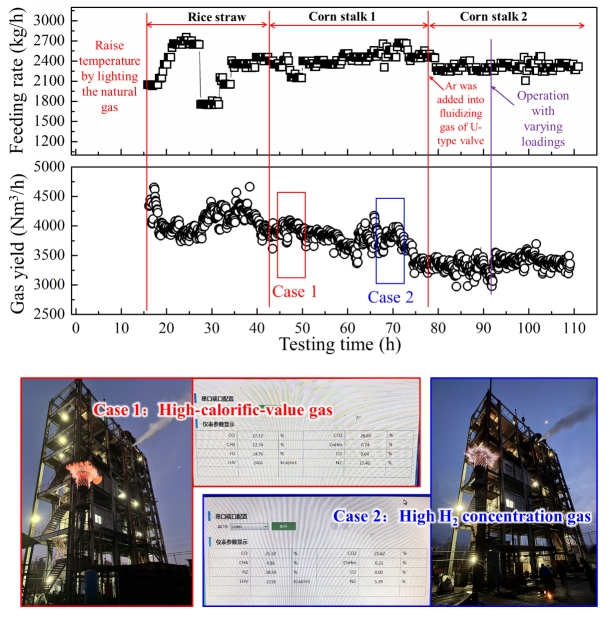

The core aim of this industrial demonstration was to verify the technical viability and continuous operability of the fluidized bed two-stage gasification process for generating high-grade fuel gas through oxygen-enriched gasification (oxygen + air + steam as the gasifying medium) and syngas via oxygen-blown gasification (oxygen + steam) using diverse biomass feedstocks. Throughout the trials, the gasification temperature was precisely controlled between 750 and 880 °C by regulating reaction parameters and oxygen/steam flow rates. The system achieved a maximum continuous operation duration of over 110 hours, as illustrated in Figure 2.

Figure 2 Variations of temperature and pressure in the industrial test of biomass fluidized bed two-stage gasification.

During the continuous operation tests, the feed rate was controlled at 2400–2800 kg/h based on the actual temperature of the gasification system, with an equivalence ratio (ER) of 0.3–0.4 and an oxygen concentration of 30–40 vol.% in the gasifying agent. The system was successfully switched between oxygen-enriched and oxygen/steam gasification modes, as shown in Figure 3. The equipment exhibited stable operating characteristics during raw material substitution and fuel throughput adjustment.

Figure 2 Variations of temperature and pressure in the industrial test of biomass fluidized bed two-stage gasification.

During the continuous operation tests, the feed rate was controlled at 2400–2800 kg/h based on the actual temperature of the gasification system, with an equivalence ratio (ER) of 0.3–0.4 and an oxygen concentration of 30–40 vol.% in the gasifying agent. The system was successfully switched between oxygen-enriched and oxygen/steam gasification modes, as shown in Figure 3. The equipment exhibited stable operating characteristics during raw material substitution and fuel throughput adjustment.

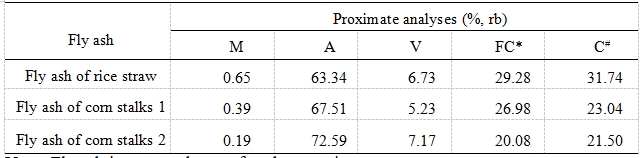

Figure 3 Continuous operation results of biomass pure oxygen/steam fluidized bed two-stage gasification.

The heating value and effective gas composition of the product gas are adjustable by modifying operational parameters. The torch flame exhibited a bright yellow hue when the product gas had a high calorific value. In experiments employing N2 as the fluidizing gas in the U-type valve, the peak calorific value attained was 10.04 MJ/Nm3 (equivalent to 2400 kcal/Nm3). As the effective syngas (CO + H2) fraction in the product gas neared 65%, the flame transitioned to a light blue color. At this point, the H2 content reached approximately 40 vol.%, while the CH4 content stood at around 5 vol.%. The equipment demonstrated good adaptability to low-quality biomass fuels such as corn stalk 2, though the high ash content in the feedstock significantly reduced gas yield. In industrial applications, superheated steam or CO2 serves as the fluidizing medium in the U-type valve, a design that can further improve the syngas quality. Table 2 shows the characterization of fly ash collected by baghouse filters, indicating that the residual carbon content in the fly ash can be constrained to ≤30 wt.%.

Note: Fly ash is received bases after the experiment, *the fixed carbon content was calculated by the differential subtraction method, #the carbon content is the result of organic elemental analysis.

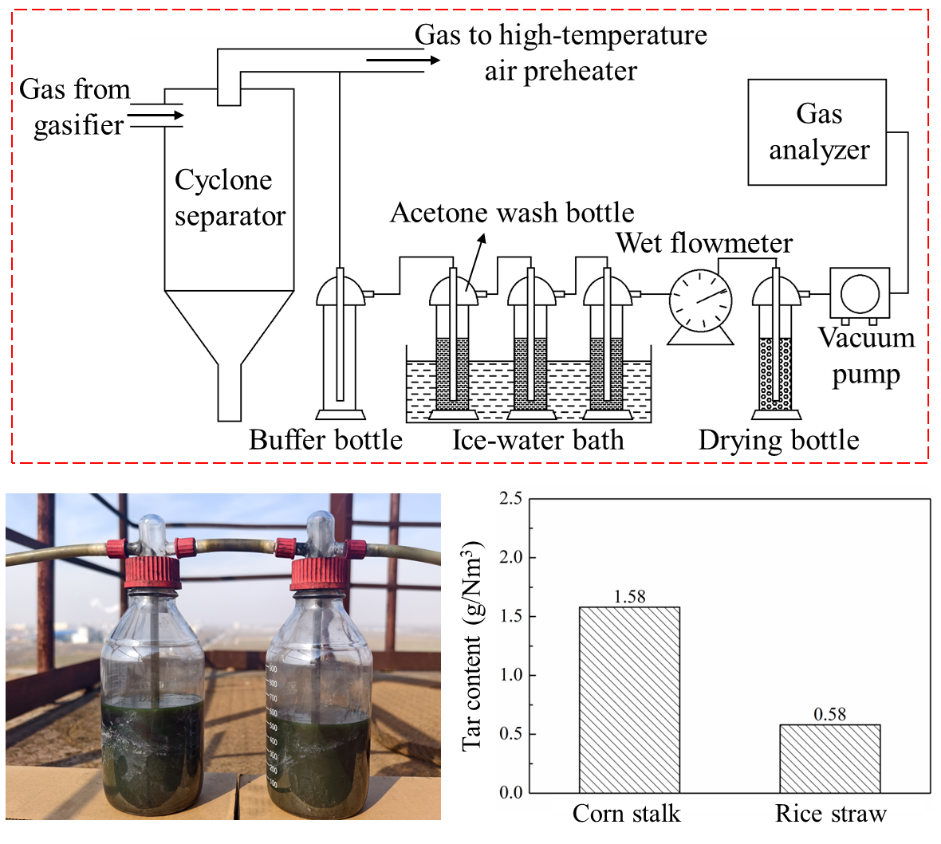

Under steady-state conditions during continuous operation, the syngas stream was sampled via a vacuum pump from the pipeline section between the cyclone separator and the high-temperature air preheater. Following passage through three ice-cooled acetone scrubbers, tar was collected for gravimetric analysis, while the purified gas sample was analyzed for composition. As illustrated in Figure 4, after 10 hours of continuous sampling, the tar content in the syngas was 1.58 g/Nm3 using corn straw feedstock, compared to 0.58 g/Nm3 with rice straw. In industrial implementations, tar formation can be further mitigated by optimizing the staged oxygen supply to regulate the gasification temperature profile. The syngas must undergo wet scrubbing to remove residual particulates and tar, thus safeguarding the operational stability and longevity of catalysts employed in sustainable aviation fuel and green methanol synthesis. The validated gasification technology reliably maintains tar concentrations within process specifications.

Figure 4 Analysis of tar content in product gas from corn stalk and rice straw gasification.

4. Conclusion

In conclusion, the experimental results conclusively validate the technical merits of the fluidized bed two-stage gasification technology, which effectively guarantees the quality of biomass-derived syngas, sustained and stable operation of process equipment, generation of ultra-low-tar gas, and compatibility with a broad spectrum of feedstocks. This confirms the viability of this innovative approach for bio-syngas production and the efficacy of its industrial-scale deployment. Significantly, this marks the pioneering industrial demonstration of biomass fluidized bed two-stage O2/steam gasification for syngas production in China, distinguished by the longest continuous runtime, most extensive array of biomass fuels tested, lowest tar content in the product syngas, and highest syngas yield documented in the domestic literature to date.

The validated fluidized bed two-stage gasification process (Figure 1) is straightforward and has been successfully industrialized in dual fluidized bed reaction systems both domestically and internationally. This technology holds great promise for advancing industrialization, emerging as a leading candidate for the core biomass gasification technology that will underpin the future “green methanol and sustainable aviation fuel industry chain”. Following successful industrial trials, our team will actively pursue engineering and industrial collaborations with major domestic and international enterprises. Specifically, we will advance the industrial demonstration of atmospheric-pressure fluidized bed two-stage gasification technology and develop process equipment for pressurized fluidized bed two-stage gasification to produce bio-syngas, thereby addressing the key challenges and bottlenecks in the industrialization of biomass-based integrated green synthesis processes.

Acknowledgement

The work was financially supported by Liaoning Province Science and Technology Plan Joint Fund Doctoral Project (2023-BSBA-266), Basic Scientific Research Project of Colleges and Universities of Liaoning Province Education Department (NO. LJKMZ20220798), Youth Fund of National Natural Science Foundation of China (NO. 22108175).

Reference

[1]. X. Jia, Z. Han, X. Jiang, Z. Zhang, D. Bai, Q. Wang, S. Sun, G. Xu, Transformation of Fossil Energy Utilization Modein Responding to the Double-carbon Targets, China Development, 4(22) (2022) 56-68.

[2]. X. Song, X. Jia, P. An, Z. Han, G. Xu, Development of science and technology in thermochemical reaction engineering, Chemical Industry and Engineering Progress, 43(7) (2024) 3513-3533.

[3]. G. Xu, D. Bai, C. Xu, M. He. Challenges and opportunities for engineering thermochemistry in carbon neutralization technologies[J]. National Science Review, 10(9) (2023): nwac217.

[4]. Z. Han, X. Jia, X. Song, P. An, L. Fu, J. Yue, J. Yu, X. Liu, Z. Zhang, Y. Jin, M. He, Bai D, Xu G, Engineering thermochemistry to cope with challenges in carbon neutrality[J]. Journal of Cleaner Production, 416 (2023) 137943.

[5]. C. Wang, X.in Jia, L. Fu, Z. Han, D. Bai, G. Xu, Innovations in engineering thermochemistry to break through critical green and low-carbon chemical technologies, Sci Sin Chim, 55 (2025) doi.org/10.1360/SSC-2025-0031.

[6]. C. Wang, X. Wang, Z. Han, M. Zhang, L. Zhu, X. Jia, P. An, D. Bai, F. Wang, G. Guan, G. Xu. Essential strategies for efficient low–tar biomass gasification: in-bed intensification and interactive two–stage reactions, Resources Chemicals and Materials, https://doi.org/10.1016/j.recm.2024.11.002.

[7]. M. Cortazar, L. Santamaria, G. Lopez, J. Alvarez, L. Zhang, R. Wang, X. Bi, M. Olazar, A comprehensive review of primary strategies for tar removal in biomass gasification, Energy Conversion and Management, 276 (2023) 116496.

[8]. U. Wolfesberger-Schwabl, I. Aigner, H. Hofbauer, Mechanism of tar generation during fluidized bed gasification and low temperature pyrolysis, Ind. Eng. Chem. Res. 51 (40) (2012) 13001–13007.

[9]. X. Zeng, Y. Dong, F. Wang, P. Xu, R. Shao, P. Dong, G. Xu, L. Dong, Fluidized bed two-stage gasification process for clean fuel gas production from herb residue: fundamentals and demonstration, Energy Fuels 30 (9) (2016) 7277–7283.

[10]. X. Zeng, R. Shao, F. Wang, P. Dong, J. Yu, G. Xu, Industrial demonstration plant for the gasification of herb residue by fluidized bed two-stage process, Bioresource Technology 206 (2016) 93–98.

[11]. C. Wang, M. Zhang, Z. Han, D. Bai, W. Duo, X. Bi, A. Abudula, G. Guan, G. Xu, Corrigendum to ’Pilot verification of a two-stage fluidized bed gasifier with a downer pyrolyzer using oxygen-rich air’, Fuel 319 (2022) 121816.

[12]. C. Wang, L. Zhu, M. Zhang, Z. Han, X. Jia, D. Bai, W. Duo, X. Bi, A. Abudula, G. Guan, G. Xu, A two-stage circulated fluidized bed process to minimize tar generation of biomass gasification for fuel gas production, Appl. Energy 323 (2022) 119639.

[13]. S. Liu, Y. Wang, R. Wu, X. Zeng, S. Gao, G. Xu, Fundamentals of catalytic tar removal over and chars in two-stage gasification of coal, Energy Fuels 28 (1) (2014) 58–66.

[14]. C. Wang, Z. Wang, M. Zhang, F. Liu, H. Li, Z. Han, X. Wu, X. Jia, G. Guan, G. Xu, Production of low-tar syngas by gasifying corn stalk in a fluidized bed two-stage system using CO2-containing reagent. Fuel 397 (2025) 135264

[15]. C. Wang, F. Liu, L. Zhu, X. Wang, C. Zhang, M. Zhang, Z. Han, X. Jia, G. Guan, X. Zeng, F. Wang, G. Xu, Two-stage fluidized bed gasification enhanced with oxidative pyrolysis for low-tar producer gas from biomass. Fuel 363 (2024) 130839.

[16]. Z. Han, S. Geng, X. Zeng, S. Xu, P. An, J. Cheng, J. Yang, F. Li, S. Zhang, M. Liu, G. Guan, G. Xu. Reaction decoupling in thermochemical fuel conversion and technical progress based on decoupling using fluidized bed. Carbon Resources Conversion 1(2) (2018) 109–25.

[17]. J. Zhang, R. Wu, G. Zhang, J. Yu, C. Yao, Y. Wang, S. Gao, G. Xu, Technical Review on Thermochemical Conversion Based on Decoupling for Solid Carbonaceous Fuels, Energy Fuels, 27 (2013) 1951-1966.

[18]. J. Zhang, Y. Wang, L. Dong, S. Gao, G. Xu, Decoupling Gasification: Approach Principle and Technology Justification, Energy Fuels, 24 (2010) 6223–6232.

[19]. J. Zhang, R. Wu, G. Zhang, C. Yao, Y. Zhang, Y. Wang, G. Xu, Recent Studies on Chemical Engineering Fundamentals for Fuel Pyrolysis and Gasification in Dual Fluidized Bed, Ind. Eng. Chem. Res. 52 (2013) 6283-6302.

[20]. S. Liu, Y. Wang, R. Wu, X. Zeng, G. Xu, Research on coal tar catalytic cracking over hot in-situ chars, Journal of Fuel Chemistry and Technology, 9(41) 2013, 1041-1049.

[21]. F. Wang, Xi Zeng, Y. Sun, J. Zhang, S. Tang, J. Yu, Y. Wang, G. Xu, Characteristics of char catalytic reforming of tar in two-stage fluidized bed, CIESC Journal, 2017, 68(10): 3762-3769.

[22]. X. Zeng, F. Wang, Y. Sun, J. Zhang, S. Tang, G. Xu, Characteristics of tar abatement by thermal cracking and char catalytic reforming in a fluidized bed two-stage reactor, Fuel 231 (2018) 18–25.

中文简体

中文简体